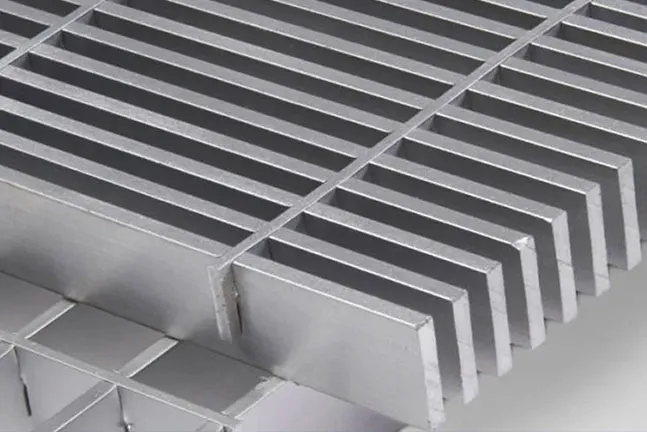

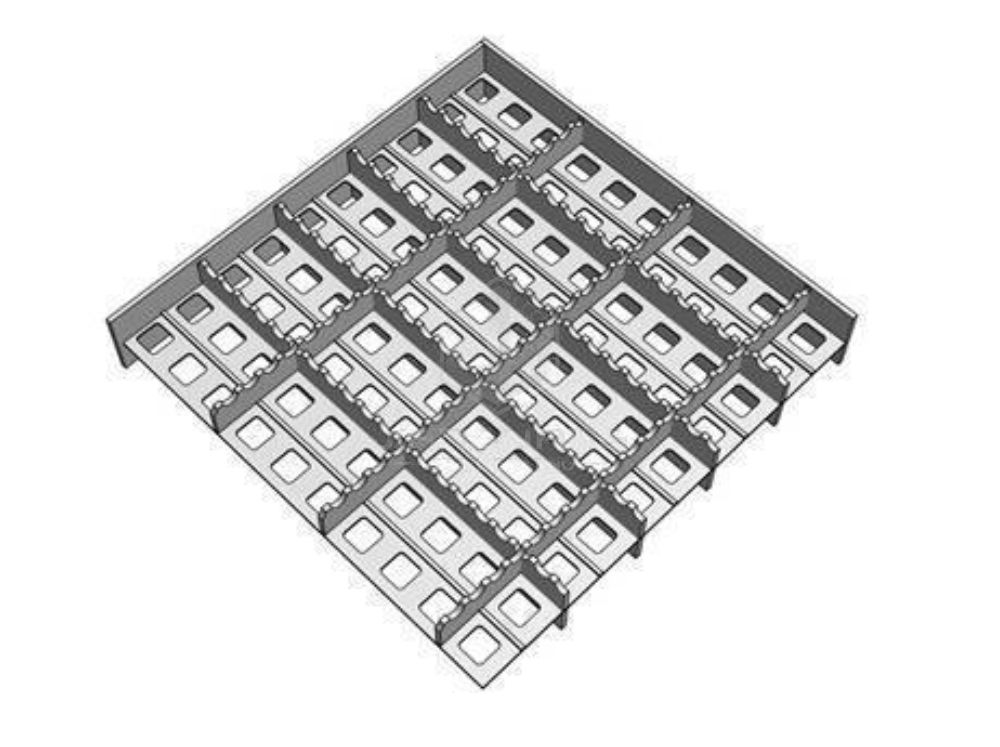

Application scenarios: Customized courtyard fences, small equipment platforms, retail market products and decorative architectural design. Service Details:

Application scenarios: Customized courtyard fences, small equipment platforms, retail market products and decorative architectural design. Service Details:

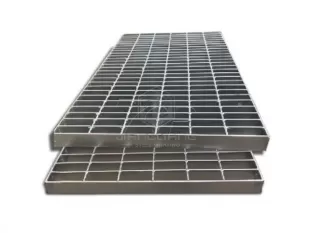

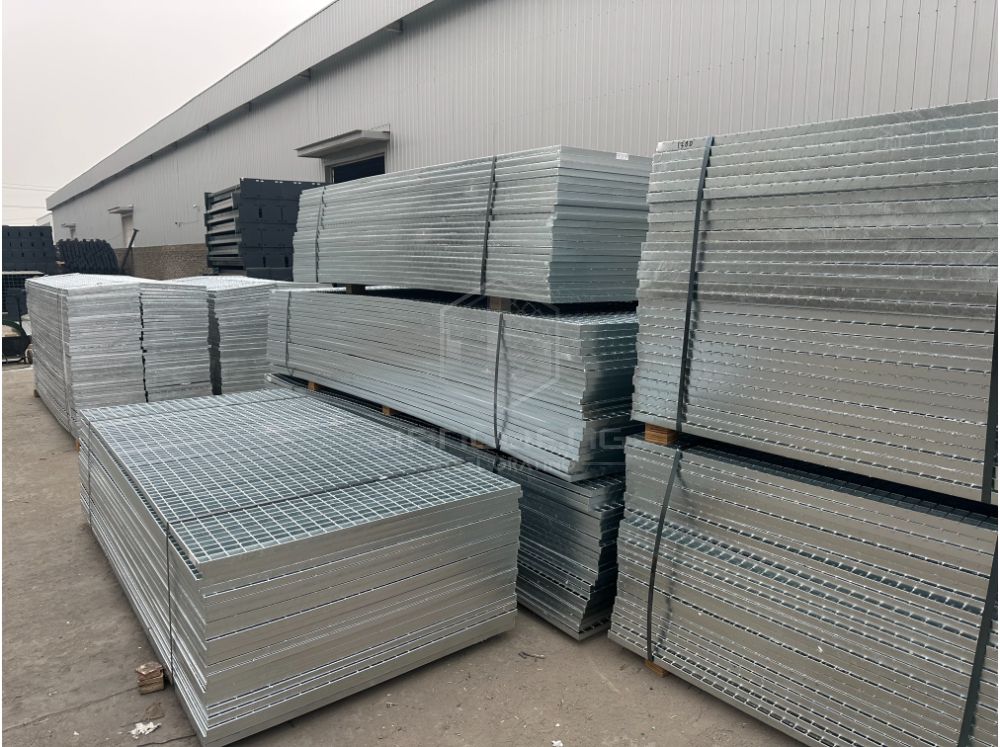

Standard products are in stock

Standard products are in stock

Customized products provide small batch production: adapt to small-scale orders, with flexible minimum order quantity.

Customized products provide small batch production: adapt to small-scale orders, with flexible minimum order quantity.

Diverse design options: provide a variety of styles and surface treatments (such as painting, hot-dip galvanizing) to meet customized needs.

Diverse design options: provide a variety of styles and surface treatments (such as painting, hot-dip galvanizing) to meet customized needs.

Provide marketing support for customers:

Provide marketing support for customers:

Provide brand services for traders, such as customized packaging and marketing materials (such as brochures, sample kits).

Provide application case photos and videos to promote sales for customers.

Fast delivery: ensure fast production and logistics support for small batch orders.

Fast delivery: ensure fast production and logistics support for small batch orders.

After-sales support and advice: provide usage and maintenance advice to extend the service life of the product.

After-sales support and advice: provide usage and maintenance advice to extend the service life of the product.

Customer case study:

Customer case study:

A retailer wanted to test the local market demand for hot-dip galvanized steel grating. We provided 100 sets of samples and designed customized packaging. After successful market testing, the customer's order volume doubled.

With these service products, Hebei Jiangliang Metal Technology Co., Ltd. is able to meet the diverse needs of buyers of all sizes, provide efficient, flexible and professional support, and ensure the best solutions for various applications.

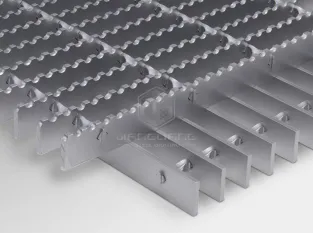

Application scenarios: Factory platforms, industrial walkways, bridge decks, large parking lot drainage systems, energy and petrochemical facilities.

Application scenarios: Factory platforms, industrial walkways, bridge decks, large parking lot drainage systems, energy and petrochemical facilities. Provide comprehensive project management: full life cycle support from demand analysis and design to installation assistance.

Provide comprehensive project management: full life cycle support from demand analysis and design to installation assistance.